SCOPE:

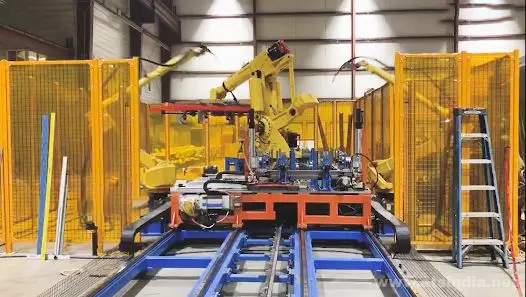

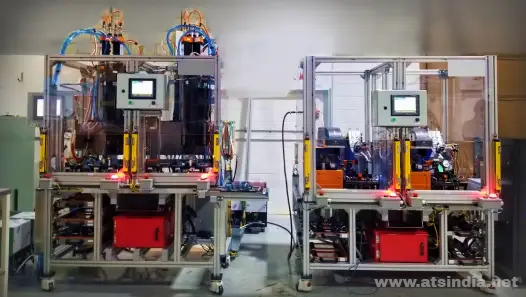

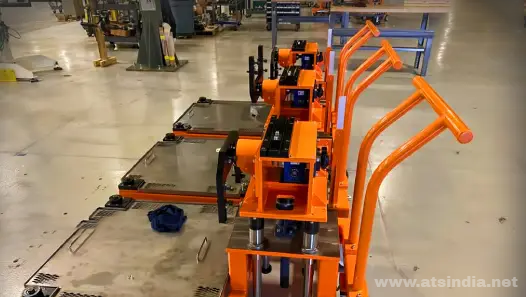

To design and build an Automated Robotic Weld Cell for door frames. The system includes the assembly of side jams and head jams with the tack weld process, full weld process, automated weld inspection, grinding process, transfer shuttle, robot EOAT, and outgoing roller conveyor.

EXISTING PROCESS:

A standalone weld fixture with manual loading/unloading, resulting in increased cycle time.

CHALLENGES:

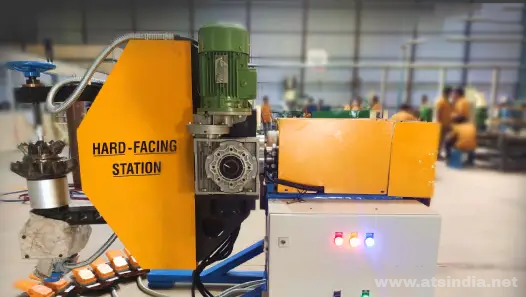

Achieving critical cycle time for the weld process, accommodating multiple product variants into a common weld station, and building a custom grinding station to grind additional weld beads at a 45° angle.

OUR SOLUTION:

ATS designed and built the complete automated robotic weld cell. The complete weld fixture was designed to accommodate all required variants and is mounted to a shuttle for transfer in and out of the robotic weld cell. Our solution achieved the required cycle time along with the quality expectations of the customer.